YOUR BROWSER IS OUT-OF-DATE.

We have detected that you are using an outdated browser. Our service may not work properly for you. We recommend upgrading or switching to another browser.

Date: 12.04.2021

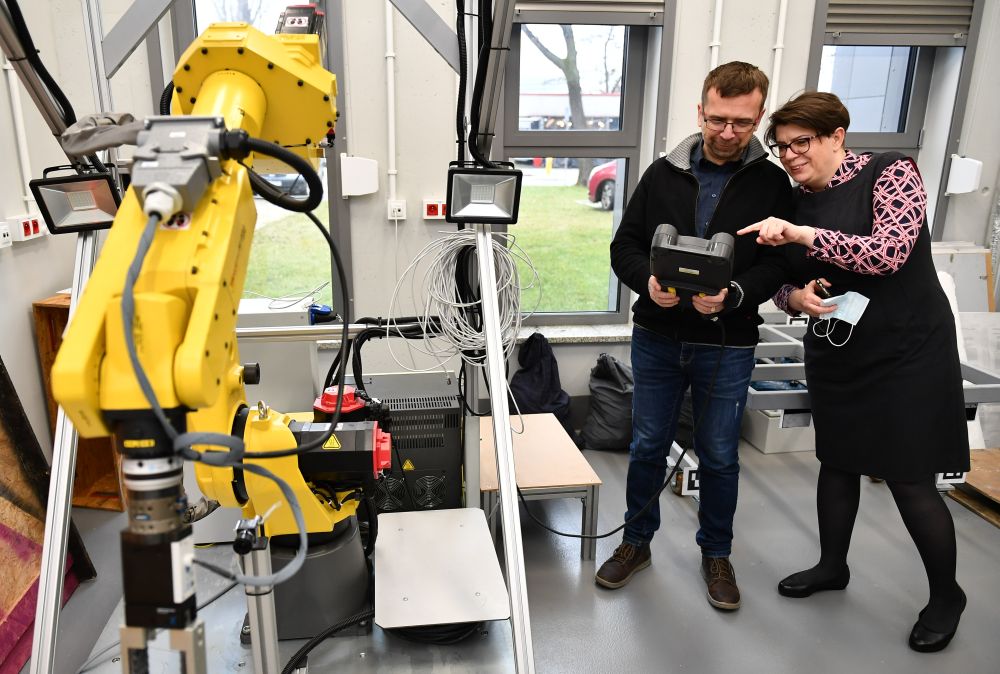

Researchers from Faculty of Geoengineering, Mining and Geology (W6) at Wroclaw University of Technology Wrocław University of Science and Technology, together with partners from Poland and Finland, are developing a system to make machinery for processing mining output even more efficient. The works are nearing completion on a solution that will improve the monitoring and diagnostics of these devices.

The mining of raw materials such as copper or silver is a multi-stage and complex process – involving not only the extraction of ore in the mine but also its appropriate processing, already on the ground surface. – Ore from KGHM mines contains an average of around 2% copper – says Prof. Radosław Zimroz, Dean of WUST’s Faculty of Geoengineering, Mining, and Geology. – From below the ground, it’s transported to an ore enrichment plant, where it’s processed into so-called concentrate, which already contains between 15 and 20 per cent of copper. For this to happen, it must undergo various mechanical processes including crushing, sifting, and grinding. The machines performing this work operate under difficult conditions – in constant dust and under varying loads and overloads. Therefore, they require special monitoring to ensure that they don’t break down and operate as efficiently as possible.

The mining of raw materials such as copper or silver is a multi-stage and complex process – involving not only the extraction of ore in the mine but also its appropriate processing, already on the ground surface. – Ore from KGHM mines contains an average of around 2% copper – says Prof. Radosław Zimroz, Dean of WUST’s Faculty of Geoengineering, Mining, and Geology. – From below the ground, it’s transported to an ore enrichment plant, where it’s processed into so-called concentrate, which already contains between 15 and 20 per cent of copper. For this to happen, it must undergo various mechanical processes including crushing, sifting, and grinding. The machines performing this work operate under difficult conditions – in constant dust and under varying loads and overloads. Therefore, they require special monitoring to ensure that they don’t break down and operate as efficiently as possible.

Professor Zimroz stresses that the classic diagnostic procedures used for machines from ore enrichment plants have proved unreliable – already at the research or testing stage, which is why it’s necessary to create a system specifically for them, using the latest technologies and solutions developed by researchers.

A system like this is being developed through collaboration within an international consortium and with funding from EIT RawMaterials – under the Horizon Europe framework programme. It’s being developed by researchers from Wrocław University of Science and Technology and specialists from KGHM Polska Miedź, Research and Development Centre KGHM CUPRUM, and the company AmePlus, as well as partners from Finland – Metso Oy, a supplier of machines and technologies, and the University of Tampere.

A system like this is being developed through collaboration within an international consortium and with funding from EIT RawMaterials – under the Horizon Europe framework programme. It’s being developed by researchers from Wrocław University of Science and Technology and specialists from KGHM Polska Miedź, Research and Development Centre KGHM CUPRUM, and the company AmePlus, as well as partners from Finland – Metso Oy, a supplier of machines and technologies, and the University of Tampere.

The project is named OPMO, which stands for  Operational Monitoring of Mineral Crushing Machinery. The result of three years’ work on the project will be a modern combined monitoring and diagnostic system for raw material processing machines, specifically: crushing machines (cone and jaw crushers) and sifters. The Finns are focusing on the crushers, while the sifters are being dealt with by scientists from Wrocław University of Science and Technology. Interestingly, the project has brought together researchers from the Department of Geoengineering, Mining, and Geology (members of the Digital Mining Center team) and the Department of Mathematics – who are taking part in OPMO to develop new algorithms that allow for the very specific "behaviour" of data collected with sensors placed on sifters.

Operational Monitoring of Mineral Crushing Machinery. The result of three years’ work on the project will be a modern combined monitoring and diagnostic system for raw material processing machines, specifically: crushing machines (cone and jaw crushers) and sifters. The Finns are focusing on the crushers, while the sifters are being dealt with by scientists from Wrocław University of Science and Technology. Interestingly, the project has brought together researchers from the Department of Geoengineering, Mining, and Geology (members of the Digital Mining Center team) and the Department of Mathematics – who are taking part in OPMO to develop new algorithms that allow for the very specific "behaviour" of data collected with sensors placed on sifters.

The solution being developed by the consortium members consists in updating existing monitoring systems, upgrading some new components, and combining available data to ensure high efficiency of processing them into information important in areas such as making decisions on planning machinery maintenance and repairs.

The solution being developed by the consortium members consists in updating existing monitoring systems, upgrading some new components, and combining available data to ensure high efficiency of processing them into information important in areas such as making decisions on planning machinery maintenance and repairs.

For companies mining mineral resources, the system will guarantee savings through process efficiency improvements. It will also make it possible to monitor the gradual degradation of machines, predict breakdowns and plan overhauls, and – as a result – increase the operational availability of machines.

OPMO research leads to developments in further fields. Among other things, the researchers are planning projects related to the development of a new sifter vibrator design, further development of algorithms created as part of the project, or work on new techniques for machine diagnostics using advanced mathematical methods. WUST staff are conducting their research in cooperation with recognised scientists from other countries, including Italy, Ukraine, and China. The members of OPMO have already authored more than a dozen scientific articles on their research under the project and published them in reputable journals. Also, implementation PhD and engineering theses are being written on the subject.

This activity has received funding from European Institute of Innovation and Technology (EIT), a body of the European Union, under the Horizon 2020, the EU Framework Programme for Research and Innovation.

EIT RawMaterials, initiated and funded by the EIT (European Institute of Innovation and Technology), a body of the European Union, is the largest consortium in the raw materials sector worldwide. Its vision is to develop raw materials into a major strength for Europe. Its mission is to enable sustainable competitiveness of the European minerals, metals and materials sector along the value chain by driving innovation, education and entrepreneurship.